Interesante nota... USAF dejando el JP-8 y pasándose al JET-A con aditivo porque éste último está más difundido:

Air Force completes historic fuel conversion

By Master Sgt. Brad West, Air Force Petroleum Agency / Published October 31, 2014

PHOTO DETAILS /

DOWNLOAD HI-RES 1 of 2

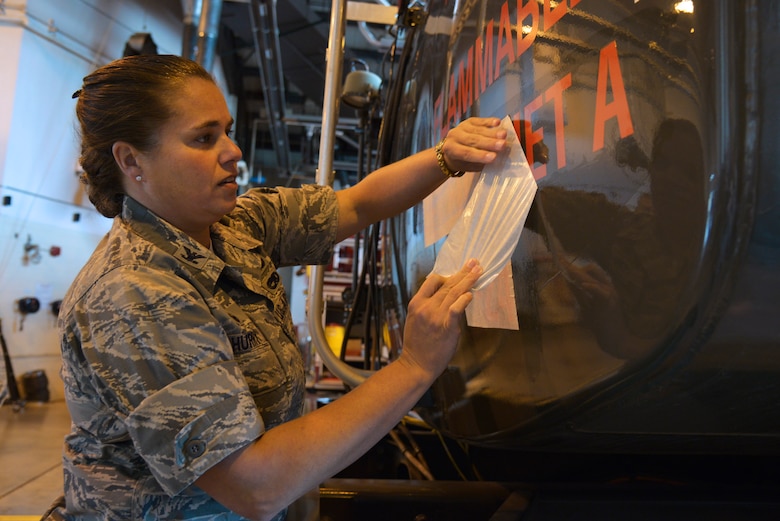

Col. Linda Hurry grinds off a JP-8 fuel decal on an R11 refueler as part of the Air Force transition to commercial jet fuel Oct. 15, 2014, Scott Air Force Base, Ill. The Jet A conversion is a Department of Defense cost saving initiative that will save the Air Force approximately $25.5 million dollars annually. Hurry is the 635th Supply Chain Operations Wing Commander. (U.S. Air Force photo/Tech Sgt. Christopher Boitz)

0

PRINT | E-MAIL

WASHINGTON (AFNS) -- The Air Force officials took an important step in fiscal responsibility and supply chain efficiency with the conversion of the final stateside installation from Jet Propellant 8 (JP-8) fuel to the more common and commercially available Jet A fuel, Oct. 29 at Wright Patterson Air Force Base, Ohio.

The transition to Jet A completed a process where the Air Force, in partnership with the Defense Logistics Agency, converted 130 stateside Air Force fuels locations in less than five years, approximately 18 months ahead of the estimated 2016 conversion completion date.

"The fuel conversion at Wright Patterson AFB marks the end of a journey and the beginning of a new era of financial stewardship for the Air Force fuels community," said Col. Linda Hurry, the 635th Supply Chain Operations Wing commander at Scott AFB, Illinois.

The Air Force Petroleum Agency (AFPET) became operationally aligned under the 635th SCOW as of Oct. 3 as part of the Future Air Force Organization initiative.

The Jet A conversion process began in 2009 as an AFSO21 cost savings initiative that incorporated Defense Acquisition Reform policy and the Energy Independence and Security Act of 2007 guidance.

"Education and open dialogue have been key to the Jet A conversion," Hurry said. "It is a true testament to our Air Force logistics leadership team and our fuels professionals, who realized the benefits associated with this conversion and accelerated the process."

"Over the past 10 years refineries were becoming hesitant to produce JP-8 fuel, as it required segregated handling and transportation. Suppliers desire to produce the commercial grade Jet A fuel, which is a fungible product and readily available." said Col. Carmen Goyette, the commander of the Air Force Petroleum Agency.

Because of its interchangeability and availability, the switch to a commercial specification product will expand the industrial base and should eventually mean lower overall aviation fuel costs for military customers, Goyette said.

Air Force bases will now receive Jet A blended with the same additives required in JP-8. Jet A with additives, has been assigned the NATO code F-24.

"Department of Defense aircraft have received Jet A at commercial airports for years and we have researched extensively, in concert with the Air Force Research Laboratory, to ensure commercial Jet A would not impact the Air Force mission," Goyette said. "Translation of the program intent to our NATO partners was key to the continued success of joint exercise and tenant programs."

Jet A (F-24) performs essentially the same as JP-8 (F-34), with the same additives, and saves everyone money, Goyette said.

The conversion allows not only the Air Force, but the Department of Defense as a whole to take advantage of a much larger commercial fuels supply chain and promises a 2 cent per gallon initial cost savings.

Two cents a gallon will yield a significant savings as the DOD spent $6.95 billion on JP-8 in 2013. The Air Force purchases more than one billion gallons of fuel annually within the CONUS, therefore the transition will save the Air Force an estimated $25.5 million in annual fuel costs and will help eliminate excess infrastructure, provide energy security and create operational flexibility for the Department of Defense.

The transition from military specification jet fuel to a commercially available jet fuel increases the agility of the Services and the Defense Logistics Agency (DLA) in their efforts to meet the warfighter requirements while simultaneously yielding multi-million dollar annual savings.

“As a result of their efforts the AF Petroleum Agency was selected for the 2013 Defense Standardization Program Team Achievement Award,” Hurry said. “This is the second consecutive year that AFPET has been recognized for exceptional Defense Standardization Program achievement.”

The Air Force took an important step in fiscal responsibility and supply chain efficiency as it converted its final stateside installation from Jet Propellant 8 (JP-8) fuel to the more common and

www.af.mil